After boiling the wort and pumping it into the Whirlpool Tank, separating the hop lees and hot coagulants, it should be cooled quickly so that the wort temperature reaches the requirements for yeast inoculation. Today, Tiantai will talk to you about cooling, a crucial step in beer brewing, and two cooling methods: one-stage cooling and two-stage cooling.

Why is wort cooling so important?

The cooling step is to create a “comfortable” fermentation environment for the wort. Wort cooling is a physical change process. In theory, it is not complicated, but due to the precipitation and separation of hot and cold coagulants, reasonable wort oxygenation, and strict hygiene requirements, the cooling process in actual production is quite complicated. Since yeast can only ferment at low temperatures, hot wort must be cooled to the fermentation temperature required by the process before inoculation. Using Plate and Frame Heat Exchanger can quickly cool the wort to the yeast inoculation temperature. Long-term slow cooling will increase the chance of harmful microorganisms in beer reproducing, so rapid cooling is very important.

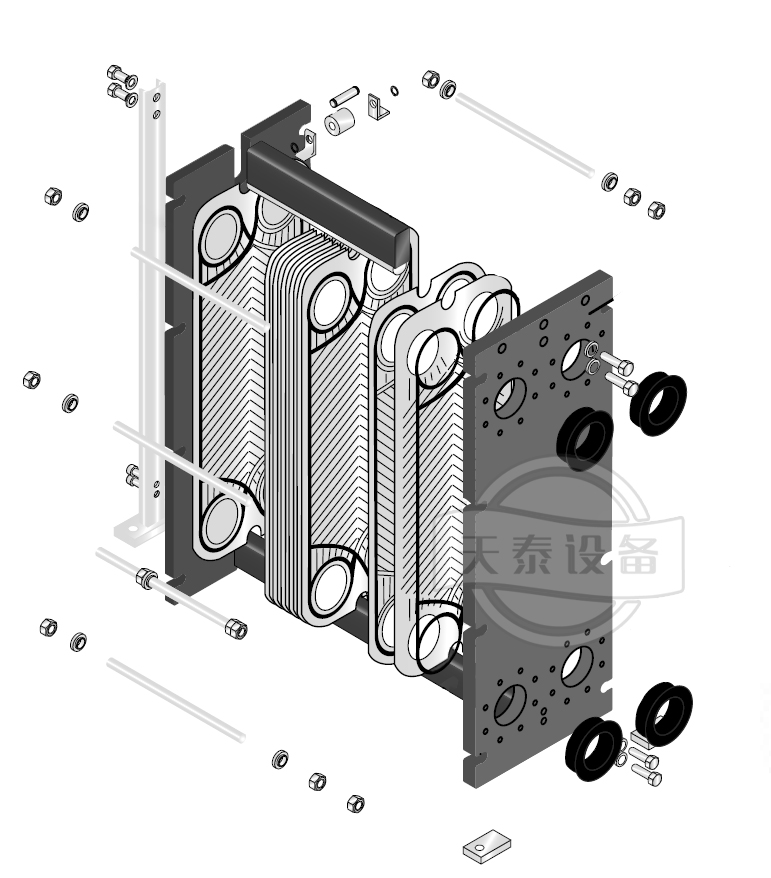

Plate and Frame Heat Exchanger

The most commonly used wort cooler in breweries is the Plate and Frame Heat Exchanger, which has a high heat exchange efficiency and has been widely used in actual production. The Plate and Frame Heat Exchanger is composed of multiple stainless steel sheets, and both sides of each sheet are covered with grooves, forming countless “small grooves”. When the wort is cooled, the hot wort and the cooling medium flow in reverse along the grooves on both sides to exchange heat. In addition, these cooling plates can be connected in parallel or in series to meet different production needs.

There are two main ways to use the Plate and Frame Heat Exchanger for wort cooling, namely the two-stage cooling method and the one-stage cooling method. In the past, the two-stage cooling method was the most commonly used, but because this method consumes a lot of energy and is complicated to operate, modern medium and large breweries prefer the one-stage plate exchange cooling method.

One-stage cooling

One-stage cooling method – first use ammonia direct cooling to cool the brewing water in the cold water tank to 3℃~4℃ (this water is commonly known as ice water), and then perform a one-time heat exchange with the hot wort in the Plate and Frame Heat Exchanger. While the wort is cooled to the fermentation temperature, the ice water is heated to about 75℃~80℃. This water can be directly used as slop washing water. Breweries that use a one-stage Plate and Frame Heat Exchanger to cool wort need to be equipped with at least one ice water tank (refrigerant), a cold water tank, a refrigerator, and often a hot water tank with an insulation layer and a heating device to temporarily store hot water for the next batch of brewing. If the cooling water is recycled, it is recommended to equip an additional hot water tank to store and heat the recycled brewing water.

Two-stage cooling

Two-stage cooling method – The two-stage Plate and Frame Heat Exchanger consists of two sections, the front and the back. An intermediate plate is installed between the two sections. The front section uses cold water for cooling, and the back section uses a refrigerant (such as ethylene glycol or alcohol solution) for cooling. The water temperature of the front section cooling is required to be below 20℃. After the front section cooling, the wort temperature is required to drop to 40℃~50℃; the refrigerant temperature of the back section cooling is -3℃~-4℃. After the back section cooling, the wort temperature is required to drop to the fermentation temperature. The water after the heat exchange in the front section can be used as feed water. The Plate and Frame Heat Exchanger has a resistance of 0.25~0.35MPa. Both the wort and the coolant need to be pumped in to directly cool the 90℃~95℃ wort flowing out of the Whirlpool Tank to the fermentation temperature. The cooling time is best controlled within 1 hour to match the production capacity of the Whirlpool Tank. Therefore, the production capacity of the late and Frame Heat Exchanger is required to be larger. Note that after using the Plate and Frame Heat Exchanger, it must be fully circulated with hot water and hot alkaline water for washing and sterilization to prevent scaling and affect the heat exchange effect.

For most modern breweries, one-stage cooling has become the preferred solution because of its easy operation, low energy consumption, and high thermal energy utilization rate. It can not only effectively improve production efficiency, but also save costs for enterprises while ensuring the quality of beer. The second stage of two-stage cooling is the refrigerant, which exchanges heat with the hot wort that is higher than the local water temperature; while the first stage of cooling is to freeze the local brewing water. The specific method to be adopted needs to be determined according to the scale, budget, and process control requirements of the brewery. Tiantai will customize the best equipment matching solution for you according to your needs. If you have any needs, please contact us.