Once the mash is complete, separating the liquid wort from the solid spent grains is crucial for efficiency, quality, and yield. Two popular methods for this separation are the lauter tun and the mash filter press. As a brewery equipment manufacturer, we often help brewers choose between these systems based on their scale, production goals, and desired efficiency.

Whether you’re a craft brewer scaling up or a large-scale producer optimizing costs, understanding these wort separation techniques can significantly impact your beer’s clarity, flavor, and overall profitability.

Understanding the Lauter Tun: traditional efficiency in wort separation

The lauter tun is a staple in many breweries, evolving from the traditional mash tun to offer improved speed and control during the sparging process. Unlike a standard mash tun, which handles both mashing and lautering, the lauter tun is specifically designed for separating wort from the grain bed after mashing.

How the lauter tun works

In a typical setup, the mashed grains (known as the mash) are pumped into a wide, shallow vessel that resembles a mash tun but is equipped with rakes instead of simple stir paddles. This design allows for a thinner grain bed, which is key to faster sparging without increasing pressure differentials that could compact the bed and slow flow.

- Role of rakes: Modern lauter tuns feature specialized rakes with zig-zag patterns and angled metal triangles. These aren’t just for show—they enhance bed permeability by gently loosening the grains if pressure builds up. In advanced systems, rakes can be raised, lowered, or rotated to fine-tune the process, preventing channeling and ensuring even extraction.

- Pressure management: Wort exits the tun through a false bottom and flows into an underback or grant—a collection vessel that allows brewers to monitor liquid levels. By comparing the height difference between the grant and the tun, you can calculate or estimate pressure across the grain bed. This prevents buckling of the false bottom and verifies optimal flow rates.

Sweet wort ready for boiling, with extraction efficiencies that are reliable for most mid-sized breweries. For example, in systems we’ve supplied, brewers report consistent yields of 80-90% without excessive energy use.

Advantages of using a lauter tun

- Cost-Effective for Medium-Scale Operations: Lauter tuns are versatile and can handle a variety of grain bills, making them ideal for craft breweries experimenting with recipes.

- Improved Permeability and Speed: The rake design maximizes efficiency during sparging, reducing the risk of stuck mashes—a common issue in traditional setups.

- Visual Monitoring: Features like the grant provide real-time feedback, helping brewers maintain quality control.

However, lauter tuns require coarser grinds and may not achieve the ultra-high yields of more advanced systems, especially with adjunct-heavy mashes.

The Mash filter: maximizing extraction for high-efficiency brewing

For breweries prioritizing maximum yield and minimal waste, the mash filter (also known as a mash filter press) represents the pinnacle of wort separation technology. This method uses mechanical pressure to squeeze every last drop of wort from the mash, often surpassing theoretical extraction limits.

How the mash filter press works

Unlike the gravity-based lauter tun, the mash filter relies on fine grinding and hydraulic pressing:

- Preparation: Grains are milled to a flour-like consistency, creating thick, porridge-like mash, mixed with hot liquor. Constant, low-shear mixing during mashing converts starches efficiently without damaging proteins.

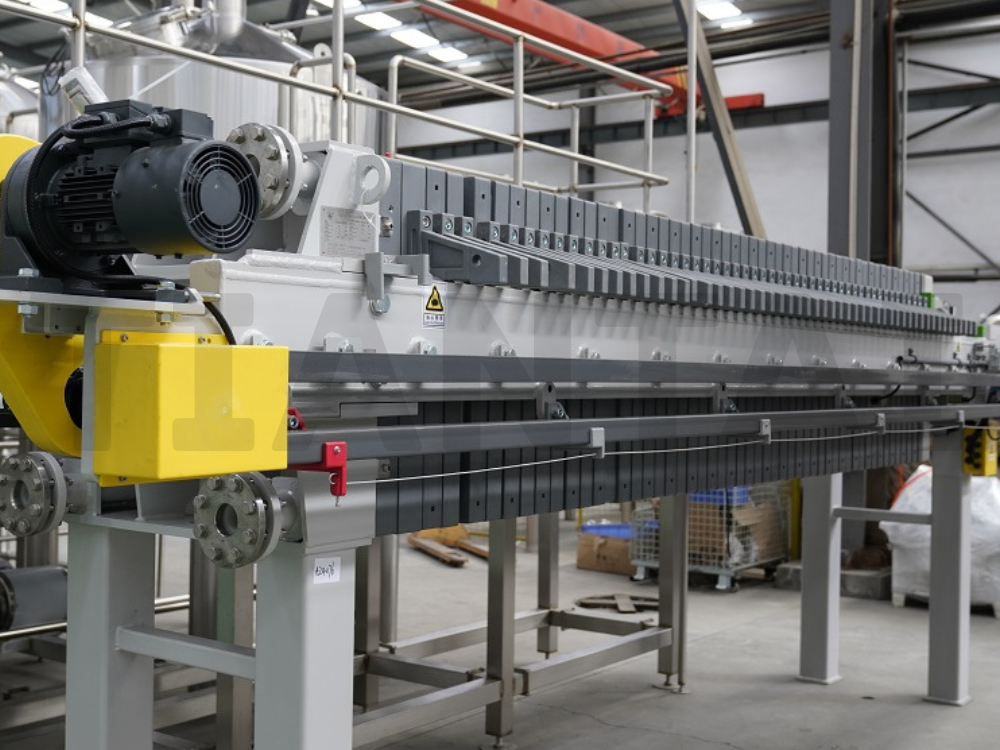

- Filtration process: The entire mash is pumped into the filter apparatus—a series of plates and frames with inflatable bladders. Once filled, the bladders squeeze the mash, forcing wort out while retaining solids. Hot liquor is then added for a second rinse and squeeze, collecting highly concentrated wort.

- Automation and cleanup: After extraction, the filter opens, releasing nearly dry spent grains onto a conveyor for easy removal. The whole process can be automated, minimizing labor.

Advantages of using a mash filter

- Superior efficiency: This is especially beneficial for large-scale operations where every percentage point matters.

- Handling fine grinds: The fine milling allows for thicker mashes and higher sugar concentrations, shortening overall brew times.

- Sustainability benefits: Less water usage in sparging and drier spent grains means easier disposal and potential revenue from by-products like animal feed.

Invented in 1901 by Phillippe Meura, the Meura mash filter has seen minor updates but remains fundamentally the same. Today, it’s used in over a third of global beer production, thanks to its plate-and-frame design that resembles other filtration systems in brewing.

On the downside, mash filters require precise control to avoid over-extraction of tannins, which could affect beer flavor. They also require a bigger upfront investment, making them best suited for high-volume breweries.

Why understand these devices?

Knowing the lauter tun and mash filter helps brewers appreciate the evolution of wort separation technology. Whether you’re starting small or scaling up, these introductions highlight their roles in efficient beer brewing. For guidance on selecting the right one, check out our companion article on choosing between a lauter tun and a mash filter.

Contact us for custom brewery equipment solutions.