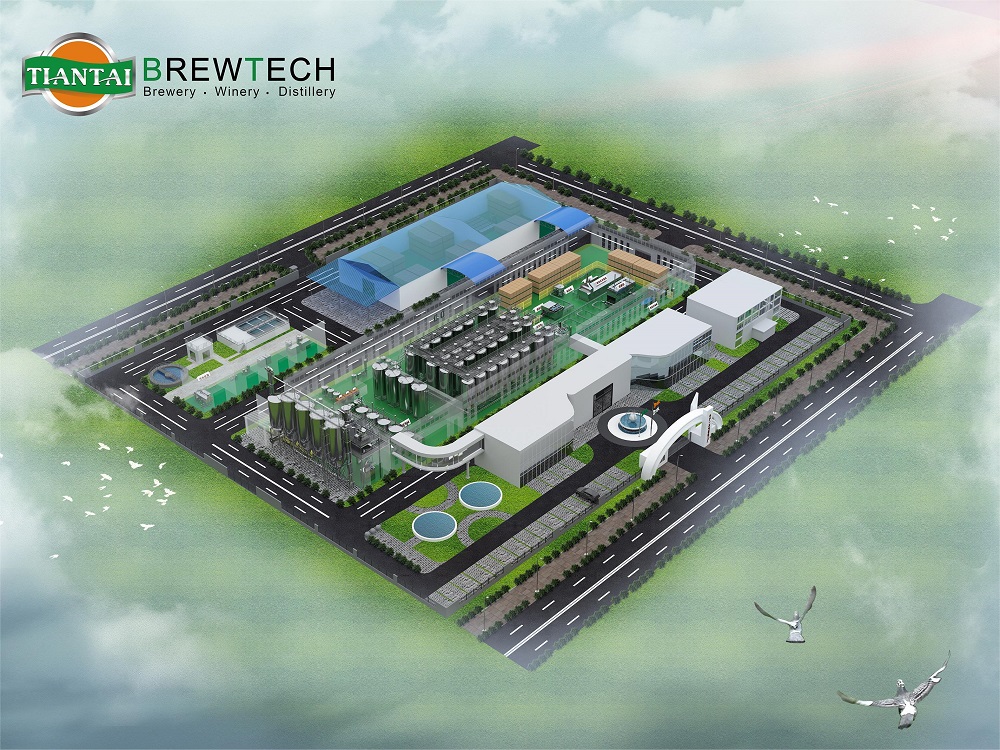

The global beer industry allocates substantial annual investments toward energy efficiency. Amid volatile energy prices, increasingly stringent environmental regulations, and intense market competition, upgrading brewing equipment to enhance energy efficiency has become a strategic approach for breweries to balance cost control, quality assurance, and environmental sustainability. As a specialized service provider in brewing equipment, with over 2,800 industry practice cases domestically and internationally and in-depth research into brewing processes, we analyze the entire brewing workflow to identify methods that help breweries reduce energy consumption and costs, offering solutions that are economical, adaptable, and stable.

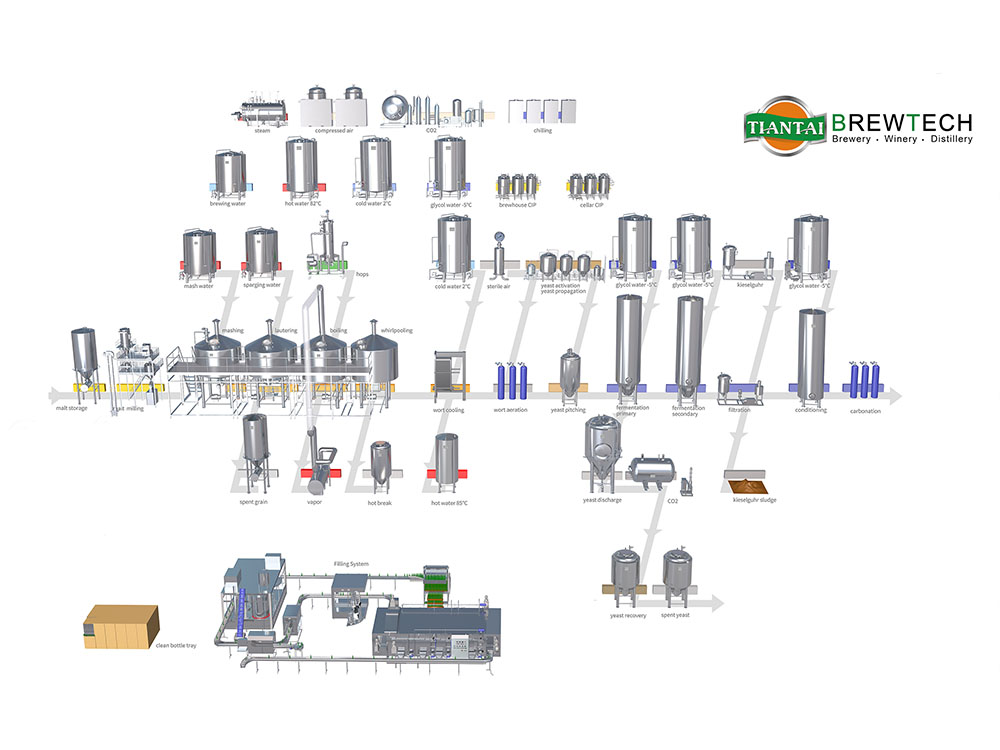

The beer brewing process encompasses grain milling, mashing, lautering, boiling, whirlpooling, cooling, fermentation, filtration, and packaging. Among these, wort boiling, cooling, and fermentation are energy-intensive stages, making them focal points for equipment optimization. Traditional brewing equipment often suffers from inefficient heat recovery, high power consumption, and inadequate process-control accuracy, not only elevating operational costs but also potentially compromising beer flavor consistency due to parameter fluctuations. Specifically, in the boiling process, large amounts of secondary steam are directly vented, resulting in significant heat energy waste and opportunities for equipment improvement and upgrade.

TianTai Solution

Energy efficiency during wort boiling hinges on effective heat recovery and precise utilization, achieved through equipment upgrades that facilitate heat reuse within brewing processes and across different stages. Integrated multi-effect heat exchange systems enable full-cycle heat recovery, offering significant benefits in energy conservation, emission reductions, cost savings, and efficiency improvements. To address the waste of secondary steam in wort boiling, TianTai proposes deploying high-efficiency secondary steam recovery systems. The condensed secondary steam generated during boiling is purified and reused for mashing and hot water preparation, enabling staged heat utilization. For example, last year, a brewery retrofitted its saccharification workshop with an efficient secondary steam recovery system that rerouted steam back into the process, supplemented by a hot water central system that diverted surplus heat to the packaging area. These measures substantially reduced overall thermal energy consumption, lowering total energy consumption by over 20% compared to the previous year, providing a replicable model for similar breweries.

In the fermentation stage, energy savings focus on heat recovery and CO₂ recycling. By optimizing fermenter cooling jackets and coil designs while integrating intelligent temperature control systems, breweries can precisely regulate fermentation temperatures, minimizing energy waste caused by temperature fluctuations and protecting yeast vitality. Additionally, sealed fermenters combined with CO₂ recovery systems enable 100% reuse of fermenter-produced CO₂, reducing purchase costs and greenhouse gas emissions. This equipment allows breweries to achieve “zero purchase, zero emission” of CO₂, delivering significant environmental and economic benefits.

Beyond core process equipment, the upgrading of auxiliary systems and comprehensive energy management throughout the production line are critical to achieving overall energy-saving goals. For more equipment upgrade solutions, please contact TianTai. Our engineers will tailor optimized solutions based on your brewery’s current conditions.

Economic viability and compatibility

Upgrades in brewing facilities must balance energy efficiency, return on investment, and process integration, safeguarding product quality and minimizing operational costs. Practical case studies indicate that many mature energy-saving technologies offer short payback periods; for instance, secondary steam recovery systems typically recoup their investment within 1-3 years through energy conservation and cost reductions. Although initial investments in control systems and CO₂ recovery units are higher, their long-term operational benefits and environmental contributions are substantial, and they often qualify for local green subsidies, alleviating investment pressures.

As an equipment provider, Tiantai adheres to the principle that process compatibility and tangible energy savings are paramount in brewery upgrades. We offer tailored solutions based on the scale of the brewery—large-scale breweries, craft brewing enterprises, or microbreweries—taking into account their process characteristics, capacity requirements, and budget constraints. For large breweries, our focus is on scalable, intelligent equipment configurations that simultaneously enhance energy efficiency and production throughput. For small and medium-sized craft breweries, we provide modular, cost-effective, energy-saving devices that preserve the unique flavor profile of the beer while minimizing energy consumption. Additionally, we deliver comprehensive lifecycle services, including installation, commissioning, operational training, and technological upgrades, ensuring long-term stable operation and continuous energy-saving benefits.

Conclusion

Reducing energy consumption is a critical factor in achieving high-quality, sustainable growth within the brewing industry. Equipment upgrades serve as the most direct and effective approach, targeting key energy-intensive processes with precise device configurations to optimize thermal, electrical, and water resource utilization. Furthermore, integrating digital and intelligent systems to establish an all-encompassing energy management framework enhances overall efficiency. As a professional brewing equipment provider, we remain dedicated to advancing brewing process technologies and equipment development, delivering premium, customized solutions to help breweries control costs, ensure quality, and achieve green, low-carbon development.