Water quality plays a pivotal role in the brewing process. Breweries require pure, contaminant-free water to create the perfect beer, and that’s where reverse osmosis (RO) equipment comes into play. Reverse osmosis is a cutting-edge water treatment technology used globally to enhance water purity by removing impurities, salts, and other unwanted elements.

What is reverse osmosis?

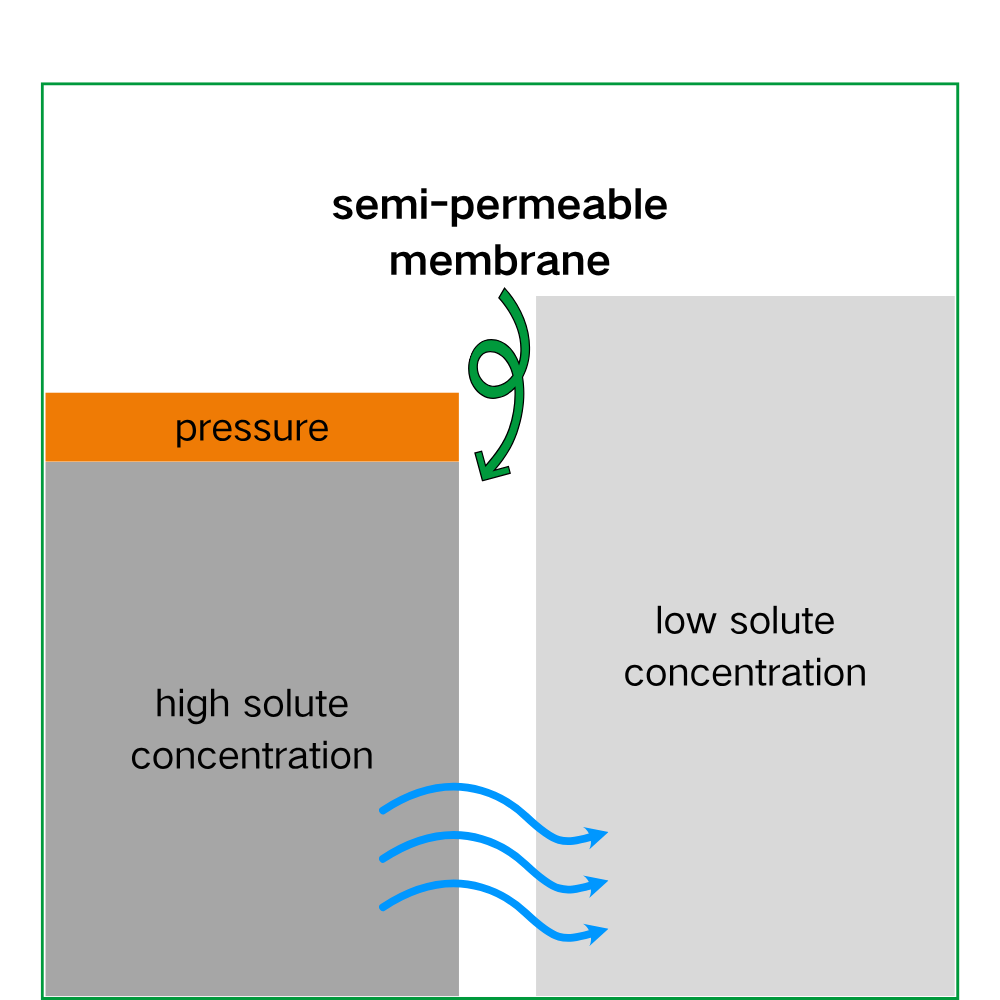

Reverse osmosis is a modern water purification method that uses a semi-permeable membrane to filter out contaminants from raw water. It seems that technology works by applying pressure to push water through the membrane, effectively removing salts, microorganisms, and other impurities. This results in pure water with minimal dissolved solids, which makes it ideal for brewing high-quality beer.

How Does Reverse Osmosis Work?

To understand reverse osmosis, let’s explore its underlying principle:

- Osmosis: In its natural state, osmosis is said to occur when water moves from an area of low solute concentration to a high solute concentration through a semipermeable membrane. The process is designed to gently balance the concentration on both sides of the membrane.

- Reverse Osmosis: The application of external pressure to the concentrated side has been found to encourage water to flow in the opposite direction. This is contrary to natural osmosis and results in water passing through the semipermeable membrane, leaving impurities behind. The process is designed to ensure that only the purest water moves through, while salts and contaminants are rejected.

In brewing, the reverse osmosis membrane plays a crucial role. The raw water, often containing salts, minerals, and other impurities, passes through the membrane. The purified water produced has a very low mineral content, allowing brewers to adjust the water profile for specific beer styles.

Key Benefits of Reverse Osmosis in Breweries

Purity of Water:

Reverse osmosis is a highly effective method of removing dissolved solids, chlorine, and other contaminants from the water supply. This ensures the water used in brewing is pure, which contributes to consistency in the final product.

Customization of Water Profiles:

One of the potential benefits of RO equipment in breweries could be the flexibility it offers in customizing water profiles, which may be advantageous in certain circumstances. Brewers have the option of using RO water as a blank canvas and adding specific minerals back into the water to optimize it for the beer style they are brewing, whether it’s a crisp pilsner or a rich stout.

Improved Flavor:

By removing undesirable chemicals like chlorine or chloramine, reverse osmosis ensures that these elements do not interfere with the taste and aroma of the beer. This results in a cleaner, more refined flavor profile in the final product.

Consistency in Brewing:

Water composition can vary significantly from one source to another. By using RO systems, breweries can ensure that the water used in each batch of beer is consistent, which leads to more predictable and reliable results.

The Role of Reverse Osmosis Membranes

The heart of reverse osmosis technology is the membrane itself. These membranes are designed to withstand the pressure required for reverse osmosis and filter out impurities effectively. In the case of breweries, specialized membranes designed for large-scale water filtration are used to handle the high volume of water required for brewing.

Applications of Reverse Osmosis in Breweries

Pre-Treatment for Brewing Water: In many breweries, water treatment is necessary to remove contaminants before the water is used in the brewing process. RO equipment serves as the first line of defense against impurities, ensuring the water is perfectly suited for brewing.

Water for Cooling and Cleaning: RO water has also been used in cooling systems and cleaning processes within breweries. Its low mineral content is believed to help prevent the build-up of scale in equipment, which could contribute to efficiency and longevity.

Softening Hard Water: It is important to note that some regions are known to have naturally hard water, which has the potential to affect the quality of beer. It is possible that reverse osmosis could effectively soften hard water by removing the excess minerals, ensuring the water profile is ideal for brewing.

Conclusion

By removing impurities, adjusting water profiles, and enhancing consistency, RO technology enables breweries to produce high-quality beer, batch after batch. As breweries strive for perfection, having access to purified water via reverse osmosis is an essential tool in their brewing arsenal.