As the global beer market matures, the construction concepts for large-scale breweries are constantly evolving. Today, the success of a brewery is no longer solely measured by its annual output; it’s also about stable production efficiency, reliable product quality, and the ability to operate and upgrade in the long term.

For investors planning to build a brewery with an annual capacity of 200,000 tons, what they truly need is not just a few sets of equipment, but a comprehensive, systematic engineering solution from initial planning to implementation. Below, we will explain the key points in the construction process using the overall design concept of a 200,000-ton-per-year brewery project as an example.

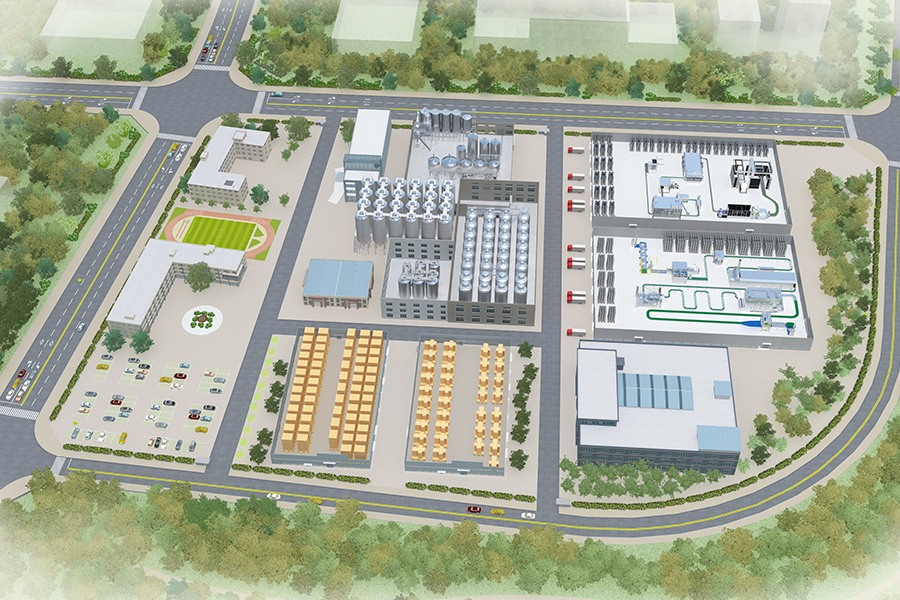

1. A Reasonable Overall Layout is the Prerequisite for Efficient Production

The construction of a large-scale brewery first requires addressing the issue of overall planning. If functional zoning is unclear, even the most advanced equipment will struggle to achieve its intended efficiency.

In this project, the factory is clearly divided according to production logic and logistics flow:

Core Production Area: The saccharification and fermentation systems are centrally located, with tight process connections, reducing material transport distances and facilitating continuous production.

Packaging and Bottling Area: The bottling workshop is located near the factory’s logistics channels for convenient and rapid finished product shipment, reducing internal transportation costs.

Raw Material and Finished Product Storage Area: Raw material and finished product warehouses are relatively independent, meeting production needs while complying with food safety and management regulations.

Utilities and Auxiliary Systems: Refrigeration, steam, CIP cleaning, and compressed air systems are centrally located for unified management and subsequent maintenance.

Administrative and Living Support Area: Maintaining a reasonable distance from the production area ensures safety and improves overall management efficiency.

This layout effectively reduces overlapping operations and improves production organization efficiency, making it a common planning approach for medium to large-sized breweries.

2. Mashing System: The Foundation for Stable Beer Production

The mashing system directly determines wort quality and also affects subsequent fermentation and final flavor. For an annual production scale of 200,000 tons, the mashing system must have the ability to operate stably over the long term.

During the design process, we consider the client’s site conditions and product planning to configure a high-capacity, highly automated mashing system. Its main features include:

Flexible process vessel configuration to adapt to various beer styles; Precise temperature and time control to ensure consistent wort quality across batches; High degree of automation, reducing fluctuations caused by manual operation; Equipped with a heat recovery system to effectively reduce steam and energy consumption.

Given the current backdrop of continuously rising energy costs, this type of energy-efficient mashing system has become the mainstream choice for industry development.

3. Fermentation System: Balancing Scale and Stability

To maintain the stability of beer flavor under high-volume production conditions, the design of the fermentation system is crucial. This project adopts a centralized arrangement of large conical fermentation tanks (CCTs).

This fermentation system has the following advantages:

Tank volume matched to production cycle, improving tank capacity utilization; Precise temperature and pressure control to ensure yeast activity and fermentation quality; High-standard stainless steel construction, meeting international hygiene and food safety requirements; Deep integration with the automated CIP system, shortening batch changeover time.

This configuration improves overall fermentation efficiency while ensuring product consistency, and is a mature practice in medium to large-sized breweries.

4. Bottling System: A Balance of Efficiency and Flexibility

As market demands become increasingly diversified, beer packaging formats are also becoming more varied. Bottles, cans, and various packaging sizes place higher demands on bottling systems.

To address this trend, we have configured a high-speed and flexible bottling system for a brewery with an annual production capacity of 200,000 tons, featuring the following characteristics:

Adaptable to various packaging formats and sizes

Low-oxygen control design effectively extends beer shelf life

High level of automation, reducing labor costs

Smooth integration with front-end and back-end production and logistics systems

This bottling configuration helps the company respond quickly to market changes and enhance product competitiveness.

5. TianTai Brewery Design Concept

From an overall perspective, the design of this 200,000-ton-per-year brewery fully reflects the current industry development trend:

Higher levels of automation and digitalization lay the foundation for a smart factory.

Emphasis on energy conservation and environmental protection reduces long-term operating costs.

Modular and scalable design facilitates future capacity upgrades.

Compliance with international health and safety standards meets export and multi-market demands.

By organically combining process design, equipment selection, and factory planning, the entire factory not only possesses high production efficiency but also excellent long-term adaptability.

Building a 200,000-ton-per-year brewery is a systematic project requiring a long-term vision. From initial planning to core equipment configuration, every step must undergo thorough evaluation and meticulous design. As a professional supplier of beer equipment and brewery engineering solutions, TianTai is always customer-oriented, committed to providing customers with efficient, reliable, and sustainable overall plant construction solutions, helping them move steadily forward in the ever-changing global beer market.