In the brewing process of craft beer, every step hides the brewer’s pursuit of quality. Today, Tiantailai and friends talk about another key link in beer brewing – vortex sedimentation and see how the brewing technology of modern breweries controls the quality of brewing and ensures the efficient operation of brewing equipment.

Hot coagulants are insoluble condensates formed by the condensation of high molecular nitrogen during the boiling process of wort, mainly composed of proteins and polyphenol complexes with a diameter of 30~80μm. In the past, open cooling plates and sedimentation tanks were common configurations, but they were not efficient in handling hot coagulants, and modern breweries rarely used them. Now most breweries have embraced more advanced vortex sedimentation equipment – Whirlpool Tank, and sometimes use centrifuges or precision filters to ensure efficient handling of hot coagulants.

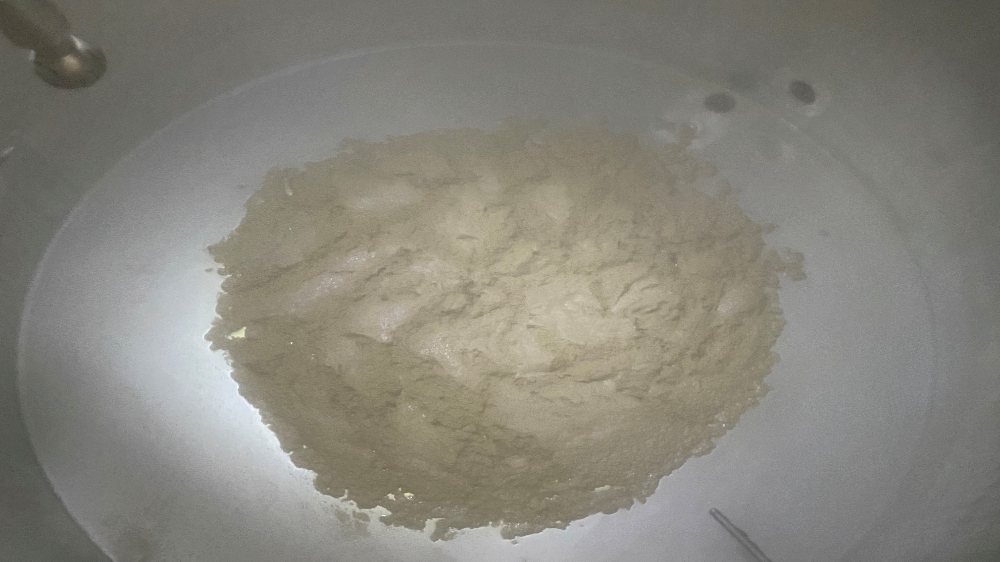

Imagine that the wort enters the tank along the tangent direction of the tank wall, forming a rotating motion of the wort. This process is like organizing an orderly flow inside the wort. After the feeding is finished, the rotating wort will naturally slow down, thus producing a whirlpool effect. The magnitude of the force at each point inside the wort varies with its location and needs to be balanced by centrifugal force and gravity. The friction resistance generated by the upper wort and the air is small, and a concave liquid surface is formed when rotating; the middle wort moves around with the centrifugal force; the wort on the wall and bottom of the tank has large friction resistance during rotation, and the rotation speed is locally slowed down. The solid particles on the wall of the tank sink due to the relatively large gravity. Under the action of overall balance, the liquid at the bottom of the tank supplements the low-pressure area formed by the centrifugal action of the upper liquid to generate centripetal force and continuously surges to the center, while also forming a central upward suction force. In this way, the solids in the wort continue to move closer to the center of the tank under the combined force of gravity and centripetal force. As the whirlpool speed naturally slows down, they settle in the center of the bottom of the tank after coming to a standstill, forming a mound. In the end, these unwanted “impurities” are completely separated from the clear wort, achieving the purpose of solid-liquid separation.

Whirlpool Tank is a flat-bottomed closed cylindrical container with a slope of 2% at the outlet. New Whirlpool Tanks generally have an insulation layer to prevent the wort from cooling. In order to better collect the hot coagulant, a conical hot coagulant collection cup is installed in the center of the bottom of the Whirlpool Tank. The wort enters the tank along a tangent line, and there are mostly two inlets: one at the bottom of the tank to avoid oxygen absorption; and the other at 1/3 of the height from the bottom of the tank. The inner wall of the tank should be smooth and clean, and the edges should be flat and without edges and corners. Do not install any objects in the tank, such as cooling pipes, iron escalators, and manhole doors protruding inward, because these things will cause local turbulence or eddy currents and affect the separation effect. A water spray ring pipe for washing is installed on the upper part of the tank. The ratio of the wort level height of the Whirlpool Tank to the diameter of the tank (height-to-diameter ratio) is generally 1: (2~3), and modern Whirlpool Tanks mostly choose a ratio of 1:3. When H/D=1, the separation effect of the Whirlpool Tank is already very good. However, in order to make the Whirlpool Tank have enough area to accommodate the hot coagulants, the common height-to-diameter ratio in actual production is 0.3~0.5. The wort outlet is always on the side of the bottom of the Whirlpool Tank. There are generally two outlets, one at 1/2 of the wort height and the other at 1/10 of the bottom. The discharge order is from top to bottom. When opening the valve, pay attention to the flow of the wort to prevent the flow from being too fast and impacting the sediment, causing the wort to become turbid. The residual wort outlet is opened at the bottom of the Whirlpool Tank. Its opening radius is determined according to the height-to-diameter ratio (H/D) and the amount of hot coagulants. It needs to be determined according to actual conditions during production. After the wort is discharged, the sediment should be removed with clean water. If a small cone is made in the center of the bottom of the tank, all the sediment should be stored to facilitate discharge; if the bottom of the tank is flat, there should be a 2% slope to facilitate cleaning. Therefore, the structural form of the bottom of the Whirlpool Tank can be varied.

The reason why Whirlpool Tank has become tt commonly used hot coagulant separation equipment is not only because of its simple structure and convenient operation compared with other separation equipment but also because it can separate efficiently. The goal of using the Whirlpool Tank to separate hot coagulants is juice turbidity <10EBC and wort solid particles <25mg/L. The hot coagulant is completely separated and can form a good coagulant mound, making the wort clear and transparent, and laying a solid foundation for the subsequent fermentation process. Moreover, it is also a vertical columnar design. After the hot wort is pumped in along the tangential direction, due to the cyclotron effect, the hot coagulant particles are deposited in the center of the tank bottom in a relatively solid mound along the direction of the combined force formed by gravity and centripetal force, achieving the purpose of solid-liquid separation. The clear wort is discharged from the side wort outlet and continues its brewing journey. So, is there any relationship between the effect of solid-liquid separation and the direction of rotation? Experiments have shown that the direction of wort rotation is related to the effect of solid-liquid separation and energy saving. The rotation of wort should utilize the “Coriolis” inertial force generated by the earth’s rotation from west to east. Therefore, the correct rotation direction in the northern hemisphere should be counterclockwise, otherwise, it will slow down and waste energy like sailing against the current. Of course, in the southern hemisphere, it is the opposite and should be rotated clockwise.

In general, the treatment of hot coagulants in beer brewing in modern breweries has changed from “rough” to “fine”. The use of Whirlpool Tank and other efficient separation methods not only improves the quality of beer but also makes the entire brewing process more scientific and environmentally friendly. For craft beer manufacturers who pursue excellent quality, the configuration of the Whirlpool Tank undoubtedly brings significant benefits. If you have beer equipment needs, remember to contact Tiantai.