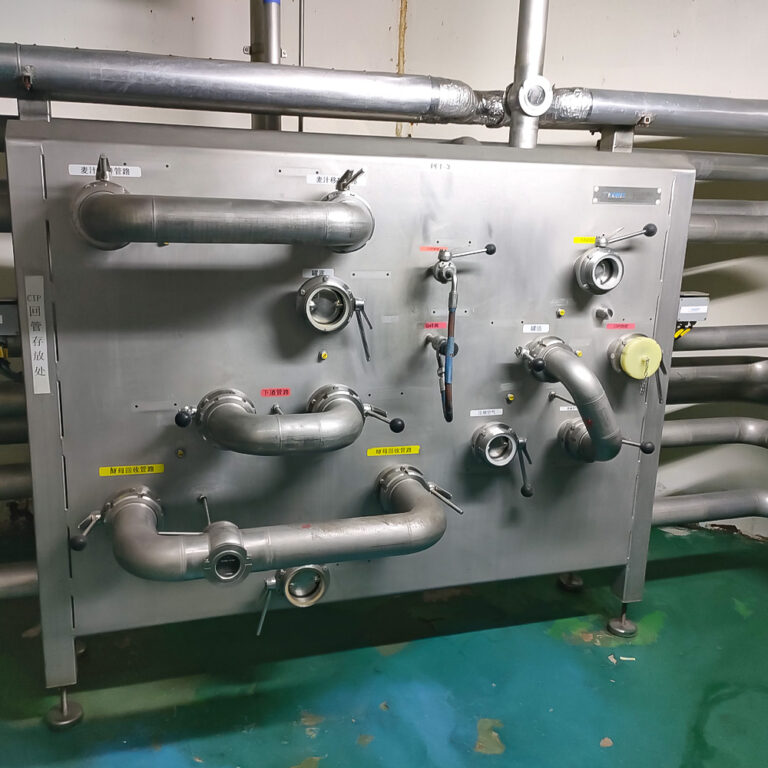

Modern breweries utilize individual CIP (clean-in-place) systems for each section, such as brewhouse, cellar, filling plant, and pipes transferring wort, etc. Cleaning procedures vary by section.

The standard cellar equipment and fittings cleaning process involves a series of rinses with various solutions, including clean water, alkali, acid, disinfectant water, and sterile water.

- The CIP system is operated automatically via PLC and sensors, including pneumatic valves, liquid level detection, flow detection, pH detection, and other sensors. The cleaning program can also be set to run automatically.

- Cleaning intensity: the design of the high-lift CIP pump and low-resistance pipeline guarantees optimal working pressure at the end cleaning device and ensures the best cleaning result.

- Heating: the high-efficiency plate and frame heat exchanger provide rapid heating and ensure the required temperature of the CIP cleaning liquid.

Configuration features

- Material: We chose big brands 304 / 316 stainless steel plates because of their acid and corrosion resistance, long-term high-temperature resistance, and reliable and guaranteed quality.

- Cleaning System: The automatic CIP System and high-quality rotary cleaning ball in this tank ensures there is no dead space, which is essential to maintaining the hygiene of the brewing process.

- Sanitary pipeline, high polishing precision, no dead ends to minimize the risk of bacterial build-up

- Our high-quality stainless steel valves include butterfly valves, angle seat valves, and diaphragm valves. They are equipped with imported valve cores that provide excellent resistance to acid and alkali corrosion, and high and low temperatures. These valves meet the highest health standards.

- Welding: The welding process uses automatic equipment to maintain a consistent temperature, reduce oxidation, and prevent ferrite precipitation. This ensures a smooth weld with high fusion and meets hygiene standards.

- All welds undergo multi-stage mechanical polishing and pickling passivation to achieve a polished inner surface with a degree of less than 0.4 microns, meeting high hygienic standards.

- Insulation: We use polyurethane thermal insulation, with a density of 40 ± kg/m³ and excellent thermal insulation performance.

- Safety: equipped with an efficient, top-quality breathing valve with positive and negative pressure protection. The pressure relief valve is designed to operate below 2 bar, ensuring tank integrity is maintained at all times.