1000L Craft brewery

A 1000L craft brewery is considered a microbrewery, and its production capacity is sufficient to supply local supermarkets, restaurants, bars, pubs. A 2- or 3-vessel brewhouse is recommended for cost-effective and space-saving operations. Additionally, a complete 4-vessel brewhouse is available for those seeking a precise process and flexible brew batch. The full set requires a moderate investment and occupies a limited area. Multiple fermentation tanks can be matched according to brewing and sales plans, which are suitable for producing various craft beer types.

The majority of sales are generated by local city sales, with a significant portion of revenue generated from the sale of cans, bottles and kegs. It is advisable to select a store location in an area with a high population density, high consumption levels, and a large demand.

| Brewhouse output per batch | 1 000 liters |

| Brewhouse structure | 2-vessel brewhouse |

| Brew batch max. | 2 |

| Cellar capacity (designed) | >20 000 liters |

| Annual total capacity (designed) | 0.3 million liters |

| Annual total capacity (max.) | 0.66 million liters |

| Annual filling capacity (designed) | 0.42 million liters |

Brewery Layout and Plan

Tiantai designs the layout according to your site and conducts beer process design to improve site utilization and save energy for you.

From production to packaging, Tiantai has you covered with malt millers, customized brewhouses, fermentation tanks, filling lines, and more brewery equipment.

Pallets *8-10 sets

Dry mills *1 unit

- Mash lauter tun *1 unit

- Brew whirlpool tank *1 unit

- Plate and frame heat exchanger *1 unit

- Wort aeration system *1 set

- Yeast pitching system *1 set

- Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

- 10HL fermenter *12 units

- 20HL fermenter *4 units

- Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– Kieselguhr adding tank *1 unit

– Front buffer tank *1 unit

– Kieselguhr mixing tank *1 unit

– Candle filter *1 unit

– Rear buffer tank *1 unit

– Bag trap *1 unit

– Other adding systems are equipped according to the process

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– 20HL bright beer tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

– Flash pasteurizer *1 unit

– Buffer tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc.

PID cabinet *1 sets

– Hot alkali tank *1 unit

– Hot water tank (sterile water tank) *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Hot liquor tank *1unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Cold liquor tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Brewing water tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Chiller *1 unit

– Glycol water tank *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Raw water tank *1 unit

– RO water treatment machine *1 unit

– Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc.

– Steam boiler *1 unit

– Distributor *several set

– Steam pipes, valves, etc

– Oil-free air compressors *2 sets

– Air buffer tank *1 sets

– Air dryer *1 sets

– Several filters

– Supporting pumps, valves, etc.

– Power cables

– Signal communication cables

– Cable bridge

– Bridge bracket

– Conduit

– Depalletizer *1 set

– Rinsing machine *1 unit

– Filling machine *1 unit

– Capper machine *1 unit

– Tunnel pasteurizer *1 unit

– Drying Machine *1 unit

– Labelling Machine *1 unit

– Inspection Machine *1 unit

– Packaging Line *1 set

– Palletizer *1 set

Brewhouse

2-vessel brewhouse structure: mash lauter tun + kettle whirlpool tun + matching pumps, valves, pipes, sensors, etc. + operation platform

Headspace of tanks: minimum 25%

Headspace of brew kettle: 30%

Material: 304 stainless steel / copper (optional)

Sparging spray ring on top of mash lauter tun with a constant flow and even rinsing of sparging water

Top-mounted rotation motor with VFD speed adjust

Manually lifted spent grain dozer for spent grain out

Side-mounted enlarged spent grain manway with glass with grain chute

Wedge wire false bottom with >17% opening rate, effectively preventing grains from trapping or clogging

Steam jackets or electricity as optional heating methods

Buffer tank keeps the balance to prevent the grain bed from collapsing

Foam detector within brew kettle detects the boiling state in the tank if there is an overflow phenomenon

Tangential inlet for proper centrifugal force for more effective whirlpool action and efficient trub collection

Single stage cooling plate and frame heat exchanger, all plates are numbered for easy disassemble and clean

Sanitary welded thermowell for high accuracy temperature sensor

Tanks are wrapped with polyurethane insulation to prevent heat loss and prevent the risk of burns

100% TIG welding with pure argon gas shield

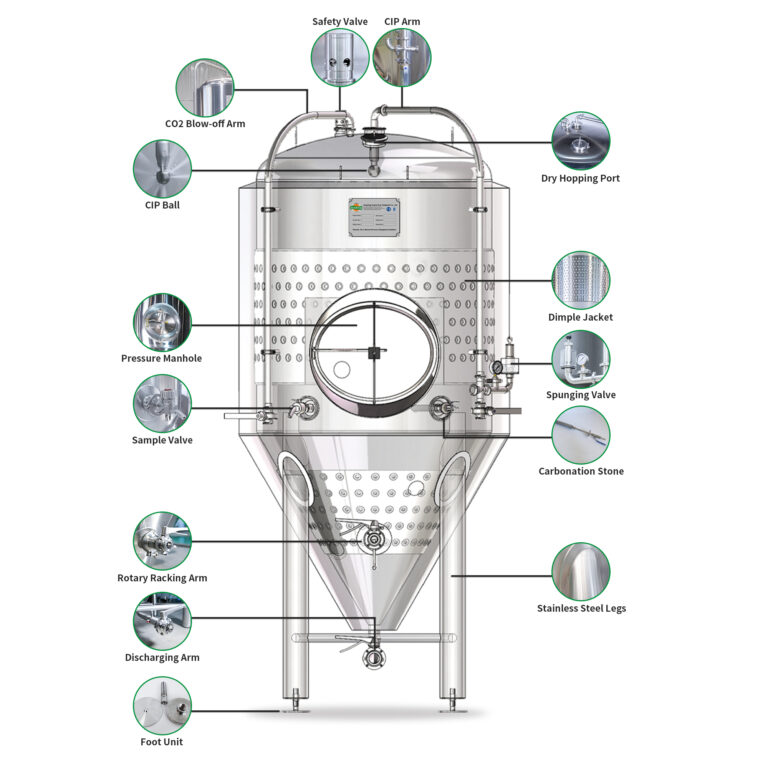

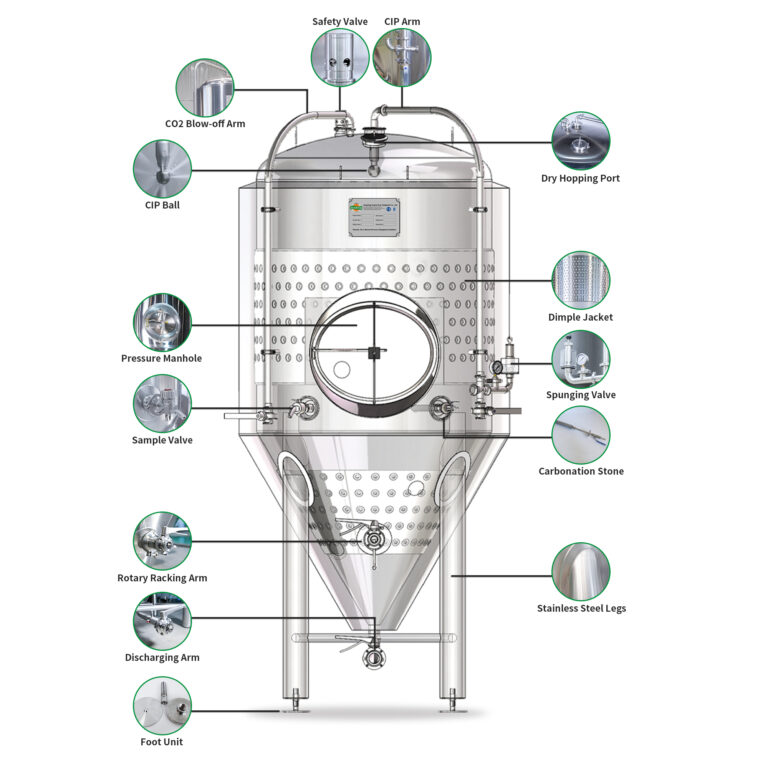

Fermentation

Fermenter material: 304 stainless steel

Headspace of fermenter: minimum 25%

Insulation: Polyurethane 80mm

Dimple plate on bottom and side wall, welded without over-burning

Conical bottom with 60° cone, optimized for excellent yeast settling characteristics and harvesting of yeast from the bottom

Top-mounted double clamp 360° rotary CIP spraying ball and port

Sanitary side-mounted oval manhole with pressured door (top-mounted available)

Carbonation port with CO2 dissolved stone 0.22um

CIP arm with four-way connection and butterfly valve

CO2 blow-off arm with butterfly valve separates from the CIP arm to avoid the spray ball getting clogged and creating pressure in the tank

Mechanical safe valve PVRV 2bar/30psi on top

Horizontal mounted rotating racking arm and port in cone with butterfly valve provides maximum beer recovery

Discharge arm with butterfly valve, removable and easy to clean

Dry hopping port with solid end cap

Our Service Process

From product testing to maintenance 10 years down the road, we are a single point of responsibility with in-house engineering, fabrication, & service.

Study/Costing

We provide you with competent and consistent support during the evaluation of your investment.

Technical Support

We offer: 2D/3D drawings, Layout plan, Interactions with civil engineering work.

Manufacturing

Using modern manufacturing techniques, we produce precise, high quality stainless steel tanks.

On-site Installation

Tiantai has professional civil and mechanical piping staff, who provide you with on-site guidance and information about their project type.

Training

Our training for you: Operator training, Maintenance training, Automation training, Individual training for your specific needs

Optimization

If you have equipment that needs upgrades or retrofitting, we can help you analyze its performance and identify areas for improvement.

Spare Parts

No down-time, only on-time.The parts you order from us are the exact same or better than those already installed in your equipment.

Maintenance

At Tiantai, we offer a remote assistance service that allows our technicians to interact with operators remotely.