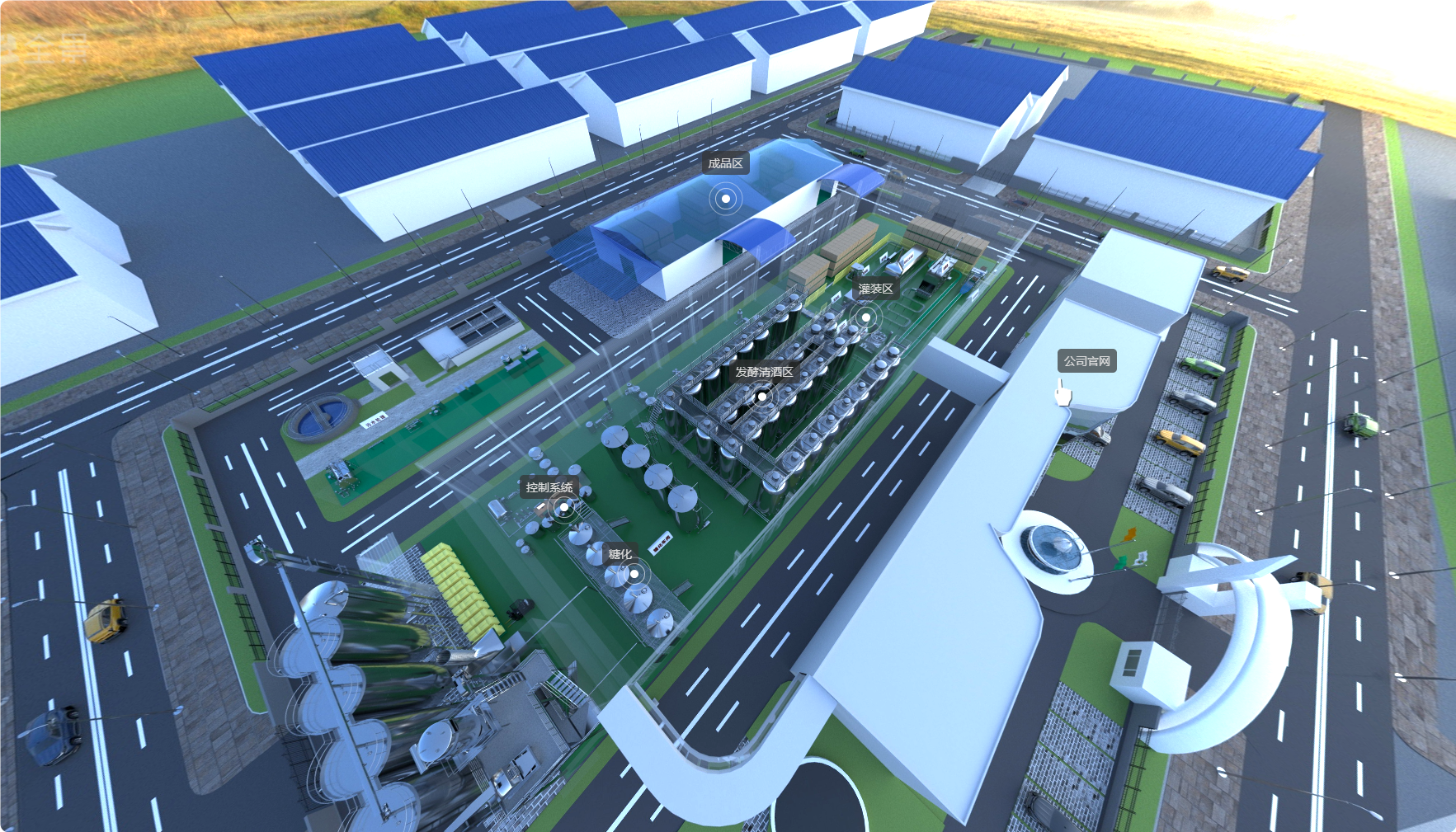

When planning a brewery facility, the equipment purchase decision-making process is influenced by a range of key design factors that ultimately determine the brewery’s performance, cost-effectiveness, and future potential. As a turnkey solution provider for breweries, it’s vital to consider these factors holistically to ensure that the facility’s operations are optimized for both current needs and future expansion.

Capital Availability

The first and most limiting factor in determining the specifications and purchase of brewery equipment is the capital available for investment. Quite simply, you cannot buy more equipment beyond what you can afford or finance. This drives decisions around equipment size, automation degree of total system, and additional features. While larger or more advanced equipment may improve long-term efficiency, the available budget will dictate initial purchases, and these decisions must be weighed against future operational costs.

Business Plan and Production Capacity

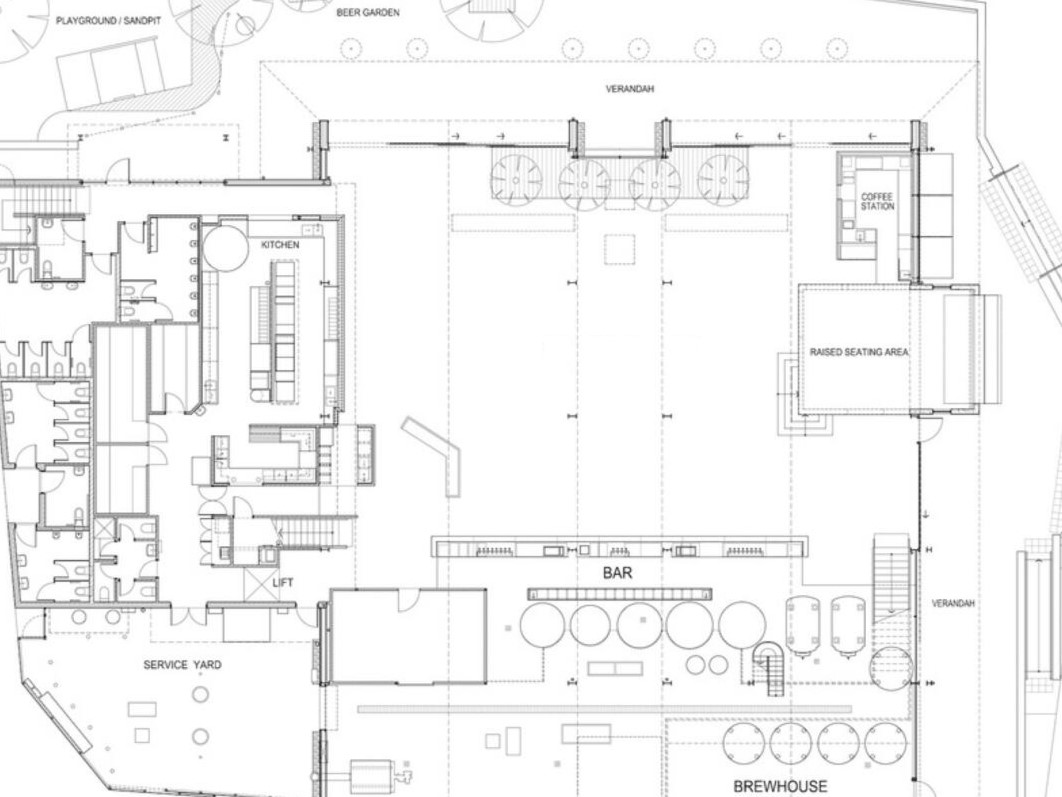

Another significant influence is the brewery’s business plan. Every brewery has a target production capacity, which is a key driver in determining the size and type of equipment needed. Whether you aim for a small, boutique operation or a large-scale beer production facility, capacity goals will influence your equipment selection. Additionally, the “style” and variety of products to be brewed will have a profound impact on the design of the facility. A brewery producing traditional lagers will often require different fermenters or bottling equipment than a craft brewery known for small-batch, experimental brews.

Marketing and Market Trends

Your marketing plan also plays a role in equipment selection. The target market not just determines what beer styles will be produced but also the flexibility the brewery needs to have. For example, will you need the ability to brew a variety of seasonal beers or specialize in a core lineup? The answers to these questions will guide equipment choices, from the versatility of the brew kettle to the flexibility of the fermentation tanks.

Regulatory Considerations

Regulatory compliance is a crucial factor that cannot be overlooked. Breweries are subject to a variety of regulations—international, federal, state, and local—that impact equipment purchases. Whether it’s ensuring the your plant meets food safety standards or navigating complex environmental regulations regarding waste treatment, all equipment must align with regulatory requirements. This can affect the layout, choice of materials, and even heating or cooling methods of the whole system.

Design Choices and Consequences

Once you have considered these factors, the next step is to make specific design choices about what equipment to purchase and how to arrange it within the brewery. Every piece of equipment comes with its own set of consequences—both expected and unexpected—that influence the overall cost of operations.

Operating Costs: some equipment may offer lower ongoing costs in the long term, even if it demands a higher initial investment. For example, investing in an automated cleaning system might require more upfront capital but can reduce long-term costs by saving on labor, cleaning materials, and waste treatment, while also improving sanitation and product quality.

Flexibility and Style: The design of your brewery impacts its ability to adapt to future trends. Some equipment choices, while optimal for specific production styles, may limit the brewery’s flexibility in experimenting with new or unconventional beer types.

Conclusion

In brewery design, every decision related to equipment specification and purchase must balance short-term feasibility with long-term strategy. A successful brewery plan considers not only current financial limitations but also future market opportunities, regulatory compliance, and operational flexibility. With the right approach, you can ensure that your brewery operates efficiently from day one while retaining the ability to grow, innovate, and adapt as your business evolves.

As a turnkey solution provider, we don’t just stop at designing and building your brewery—we stand by your side through every stage of your journey. Whether you’re just evaluating an investment, need precision engineering support, or want to optimize existing equipment, our team delivers the expertise and reliability needed to turn your brewery vision into reality. From detailed planning and high-quality manufacturing to on-site installation, tailored training, and ongoing support, we ensure that your brewery runs at its best, now and in the future. With Tiantai, you’re not just investing in equipment, but in a long-term partnership for success.