Opening an industrial brewery with an annual production capacity of 100,000 kiloliters (100 million liters) is a major investment that requires careful planning and thorough preparation. Whether you are an entrepreneur entering the brewing industry for the first time or an experienced brewer looking to expand production, understanding the required equipment, design considerations, and construction requirements is critical to the successful establishment of a brewery. This article provides a systematic overview of equipment configuration, design planning, infrastructure, and supporting systems.

1. Production Scale

Before discussing equipment and infrastructure, it is essential to understand the scale of the brewery. A brewery with an annual capacity of 100,000 kiloliters is considered a large industrial facility. For reference, this corresponds to an average daily output of approximately 300–350 kiloliters, depending on the production cycle. Such a brewery will likely operate year-round, with production plans adjusted according to seasonal demand and product variety. Multiple production lines are required, covering brewing, packaging, storage, and distribution. In addition, a large workforce and a well-structured management system are necessary to ensure smooth operations and effective quality control.

2. Equipment Configuration

An industrial brewery of this scale requires specialized equipment to support high-volume production while maintaining consistent product quality. The core equipment required for a brewery with an annual output of 100,000 kiloliters includes the following:

Brewing Equipment

Mash Tun

The mash tun is used to heat malt and mix it with water to extract fermentable sugars. Depending on the system configuration, the mash tun typically handles 50 to 100 hectoliters of wort per batch.

Lauter Tun (Filter Tank)

After mashing, the wort must be separated from the spent grain. The lauter tun performs this function and typically includes a false bottom and a rake system to ensure efficient wort filtration.

Boiling Kettle

The wort is boiled with hops in the kettle to extract bitterness and aroma. Large-capacity kettles are required to handle high production volumes, and multiple kettles are often used to enable continuous production.

Fermentation Tanks (CCTs)

Fermentation is one of the most critical stages of the brewing process. To process large volumes of beer, a significant number of temperature-controlled fermentation tanks—also known as conical fermentation tanks or CCTs—are required. A brewery of this size typically needs 100 to 150 fermentation tanks, each with a minimum capacity of 100 hectoliters (100 HL).

Bright Beer Tanks (BBTs)

After fermentation, the beer is transferred to bright beer tanks for maturation and conditioning. These tanks ensure proper carbonation and stabilization before packaging.

Packaging Equipment

Bottling Line

Due to the large production volume, a high-speed bottling line is essential. This includes automatic bottle washers, fillers, capping machines, and labeling systems. A brewery of this scale typically operates bottling lines capable of filling 20,000 to 36,000 bottles per hour.

Canning Line

In addition to bottled beer, many breweries also produce canned beer. High-speed canning lines can fill and seal cans at similar speeds, usually ranging from 20,000 to 40,000 cans per hour.

Kegging System

Kegs are commonly used for draft beer. A dedicated kegging system is required to fill kegs efficiently at high speed, ensuring timely distribution to the market.

Auxiliary Systems

Cooling System

Industrial-scale brewing requires large refrigeration systems to maintain proper fermentation and maturation temperatures. These systems typically use ammonia or glycol as cooling media.

Water Treatment System

Water is the primary ingredient in beer, making water quality critical. Water treatment systems—including filtration, softening, and reverse osmosis—are essential to ensure consistent product quality.

Steam Boiler

Steam boilers provide the heat required for brewing processes, particularly for mash tuns and boiling kettles.

Clean-in-Place (CIP) System

To maintain hygiene and product quality, an automated CIP system is necessary. This system cleans brewing equipment between batches without the need for manual disassembly.

3. Facility Layout

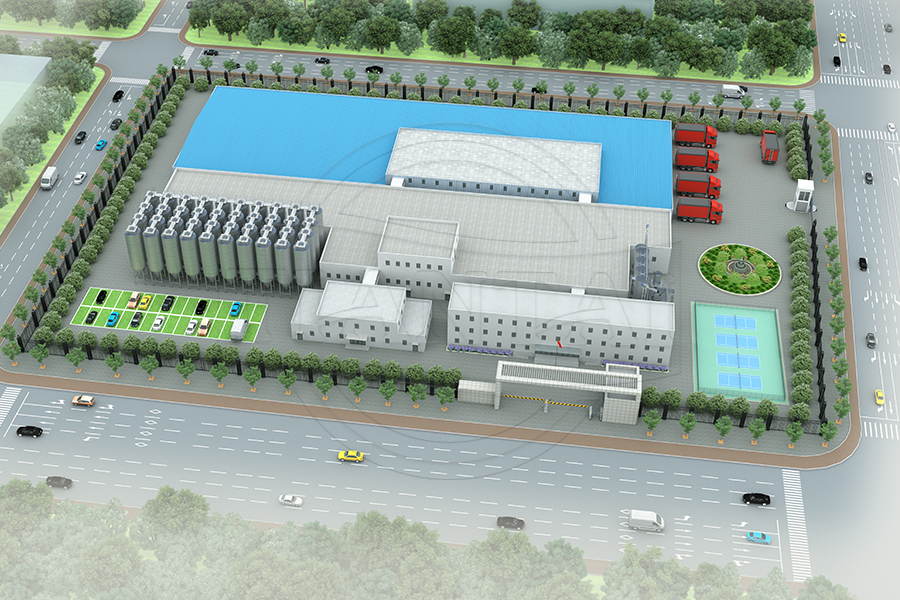

Designing an industrial brewery with an annual capacity of 100,000 kiloliters involves multiple considerations, from production area layout to the integration of auxiliary systems. Professional engineering and design services are essential to create detailed drawings and ensure regulatory compliance.

Brewing Process Design

The brewery layout should optimize the flow of raw materials, finished beer, and waste. Production is typically divided into distinct areas such as the brewhouse, fermentation area, packaging hall, and storage facilities. Careful planning is required to ensure efficient and safe material movement between these areas.

Future Expansion Space

A well-designed brewery should allow for future expansion to accommodate increasing production demand. The initial design should reserve sufficient space for additional fermentation tanks, packaging lines, and storage areas.

Health and Safety Compliance

Brewery design must comply with local health and safety regulations, including ventilation, fire protection, and hazardous materials handling. Industrial breweries require robust safety systems such as fire suppression systems, emergency exits, and adequate space for maintenance and cleaning.

Environmental Considerations

Environmental impact is a key factor in brewery design. To minimize the carbon footprint, the facility should include wastewater treatment systems, energy-efficient lighting, and waste management facilities.

4. Utilities and Infrastructure

To support the operation of a large brewery, several utility and infrastructure systems are required, including:

Power Supply

A reliable power supply is critical for brewery operations. Backup generators are recommended to ensure uninterrupted production during power outages.

Wastewater Treatment

Breweries generate large volumes of wastewater, which must be treated to comply with environmental regulations. Large breweries typically require an on-site wastewater treatment plant.

Transportation and Logistics

A strategically located site with convenient access to major highways and distribution centers is essential for the efficient transport of raw materials (such as malt and hops) and finished products.

5. Regulatory Approvals and Permits

Before constructing a brewery, all required permits and licenses must be obtained. These typically include:

Construction Permits

Compliance with local planning regulations and building codes is mandatory.

Health and Safety Approvals

Food and beverage production facilities must be approved by relevant health and safety authorities to ensure sanitary conditions.

Environmental Permits

Breweries must comply with environmental regulations related to wastewater treatment, air quality, and energy consumption.

Alcohol Production License

In many countries, a license is required for the legal production and sale of alcoholic beverages.

Whether you are entering the brewing industry for the first time or expanding existing capacity, the right strategy and thorough preparation will lay a solid foundation for success. By ensuring efficient operations at every stage and maintaining a strong focus on quality and safety, your brewery can stand out in a highly competitive market and achieve long-term commercial success.