Selecting the right wort separation equipment is crucial for brewery success, as it impacts efficiency, costs, and beer quality. If you’re familiar with the basics of the lauter tun and mash filter press (as covered in our previous introductory article), the next step is evaluating which one fits your operation. As brewery equipment experts, we’ll compare these systems and provide practical advice to help you decide.

When choosing between a lauter tun and mash filter press, consider your brewery’s scale, budget, and goals:

| Feature | Lauter Tun | Mash Filter |

| Grain Grind | Coarser (standard mill) | Finer (flour-like) |

| Sparging Speed | Moderate, aided by rakes | Fast, via mechanical pressing |

| Scale Suitability | Small to medium breweries | Large-scale, high-volume operations |

| Pressure Control | Gravity and visual monitoring | Hydraulic bladders |

| Initial Cost | Lower | Higher |

| Maintenance | Rakes and false bottom checks | Bladder and plate inspections |

Lauter tun excel in flexibility and ease of use, making them popular for craft brewers who value tradition and recipe variety.

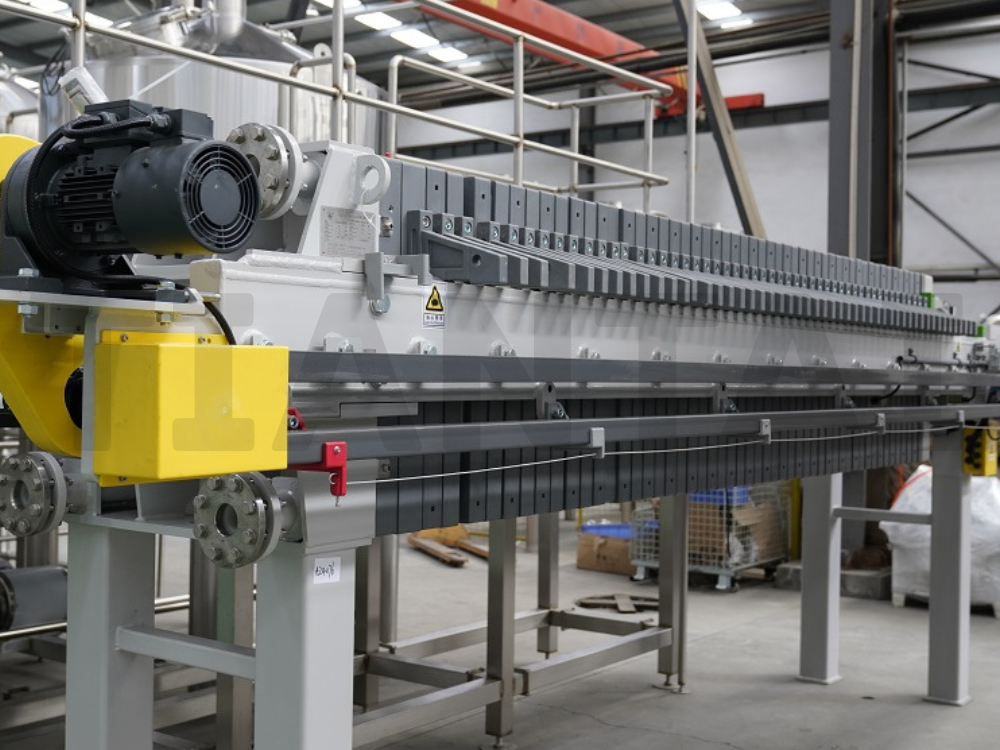

Mash filters, with their roots in early 20th-century innovation, dominate in efficiency-driven environments like macro breweries.

In our experience supplying equipment to breweries worldwide, the choice often boils down to throughput. If you’re producing under 10,000 hectoliters annually, a lauter tun might suffice. For larger operations, the mash filter’s ROI through saved grains and time is unbeatable.

Conclusion: Optimize your brewing process with the right equipment

Both the lauter tun and mash filter press play vital roles in brewing beer, efficiently converting mash into high-quality wort. By selecting the system that aligns with your brewery’s goals—whether it’s the rake-enhanced permeability of a lauter tun or the bladder-squeezed precision of a mash filter—you can enhance yield, reduce costs, and produce exceptional beer.

As a leading manufacturer of brewery equipment, we’re here to help you integrate these technologies seamlessly. Contact us today to discuss custom solutions tailored to your needs. Cheers to better brewing!